In recent years, the concept of a circular economy has gained significant attention as a sustainable alternative to the traditional linear model of production and consumption. Shifting towards a circular economy holds immense potential to minimise waste, preserve resources, and foster long-term environmental benefits. However, achieving this transition requires businesses and governments to address several challenges and barriers. This article will delve into these hurdles, explore policy measures and incentives that can drive circular practices, and shed light on innovative technologies and collaborative efforts shaping a more sustainable future.

Identifying Challenges and Barriers

Moving to a circular economy isn’t a walk in the park. Here are some key challenges faced by businesses and governments.

Mindset and Awareness

One of the primary challenges is transforming the traditional linear thinking prevalent in our society. Shifting from a “take-make-dispose” mindset to one focused on resource conservation and recycling requires changing perspectives and behaviour at all levels. We must transform our thinking and embrace a resource conservation and recycling culture.

Infrastructure and Supply Chains

To make the circular economy work, we need the proper infrastructure. That means efficient systems for collecting, sorting, and processing waste materials. Unfortunately, not every country has this in place yet. This problem is especially prevalent in developing countries. For this reason, more than half the world’s plastic litter originates from China, Indonesia, the Philippines, Thailand, and Vietnam.

Economic Incentives

Source: sweden.se/climate/sustainability

Change can be costly in the short term. In the current economic system, where the cost of recycling or reusing materials often outweighs the cost of virgin resources, there is a need for financial incentives to encourage businesses to adopt circular practices. Sweden is one such country that has successfully boosted its citizens to recycle by incentivizing the process. Sweden has one of the highest recycling rates in the world. They achieved this by implementing a “pay-as-you-throw” system, where residents are charged based on the amount of waste they generate. This incentive-based approach has led to an impressive recycling rate of over 99% for some materials.

Policy Measures, Regulations, and Incentives

As seen in Sweden, governance plays a pivotal role in transitioning to a circular economy. Here are some policy measures, regulations, and incentives that can facilitate the adoption of circular practices.

Extended Producer Responsibility (EPR)

Source: tomra.com

Extended producer responsibility (EPR) aims to hold product makers financially accountable for different stages of the life cycle of their goods, such as take-back, recycling, and final disposal at the end of their useful lives. By implementing EPR regulations, governments can encourage producers to design products with recyclability and reusability in mind. An example of EPR is the deposit return scheme. Deposit return schemes encourage customers to recycle their beverage containers by offering them cash incentives. The programmes operate by adding a deposit to the cost of a drink, which is then reimbursed to the customers when they recycle the empty drink containers, frequently at a reverse vending machine. Because of deposit return schemes, many discarded drink containers are being cleaned, reduced to little bits of raw material, and turned into brand-new bottles and cans.

Tax Incentives and Subsidies

Offering tax incentives and subsidies to businesses that adopt circular practices can provide the necessary financial boost for transitioning and overcoming initial cost barriers and sparks their interest in going circular. Across the globe, up to 20 countries are actively levying green taxes and offering green incentives in the form of cash grants, soft loans, and tax incentives to accelerate meeting their sustainability goals.

Collaborative Initiatives and Partnerships

Encouraging collaboration between businesses, governments, and non-governmental organizations (NGOs) can foster knowledge sharing, resource pooling, and collective action toward achieving circularity. Public-private partnerships and industry-led initiatives have proven successful in driving circular economy agendas. When we work together, amazing things happen.

Innovative Technologies and Collaborative Efforts

Innovative technologies and collaborative efforts greatly aid the transition to a circular economy. Here are a few examples:

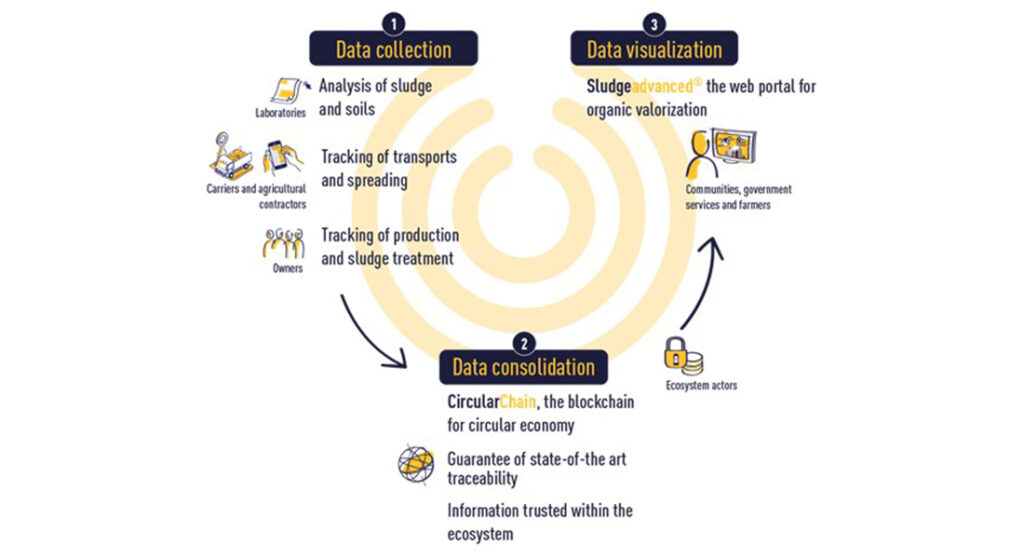

Digital Solutions and Blockchain

Digital technologies and blockchain can revolutionize supply chains. They enhance transparency and efficiency, allowing us to manage resources better and track materials throughout their lifecycle. Blockchain has been particularly effective in monitoring non-biological materials, allowing for informed decision-making and quantifying reductions in the use of virgin materials. Companies like Suez and Coca-Cola have utilized blockchain to record and manage the transfer of waste sludge and track recycled materials, respectively. By storing detailed data accessible through QR codes or RFID, blockchain facilitates shared responsibility and empowers end-users to make informed decisions regarding product repair or disposal.

Industrial Symbiosis

Industrial symbiosis promotes the exchange of waste, by-products, and energy between companies, transforming one company’s trash into another’s raw material. This collaborative approach fosters resource optimization and reduces waste generation. One company’s waste becomes another’s treasure.

Four neighbouring industrial facilities in the Kalundborg municipality of Denmark have evolved a cooperative system over the last 20 years that have significantly reduced their collective energy consumption and coal, oil, and water use therby reducing their environmental impact.

Material Innovation

We’re witnessing incredible advancements in material science. Biodegradable and compostable materials are on the rise, reducing our dependence on single-use plastics. Plus, using recycled or upcycled materials in product manufacturing is becoming the norm. Australian leather brand Bellroy and US textile company Natural Fiber Welding have created a plant-based leather alternative called Mirium. Similarly, Germany’s Revoltech uses hemp waste, and Peelsphere, which uses fruit waste and algae, is leading the way in making bio-leather the norm.

As businesses and governments embark on the journey toward a circular economy, it is essential to acknowledge the challenges and barriers that lie ahead. By implementing appropriate policy measures, regulations, and incentives and embracing innovative technologies and collaborative efforts, we can pave the path to a more sustainable and circular future. The transition to a circular economy is not only an environmental imperative but also a tremendous opportunity for resource preservation, and a better quality of life for present and future generations.